Video Date: 2018

Ansys for Ferrari Competizioni GT

A Partnership We Can All Trust

Ferrari Competizioni GT: Innovating and Winning with Ansys Simulation Technologies

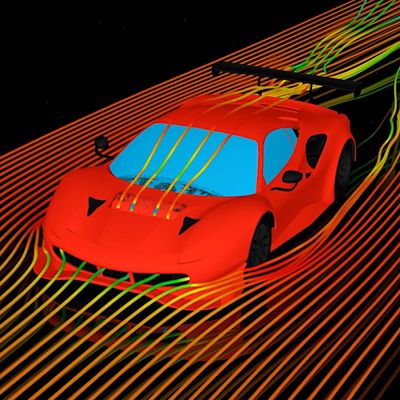

Ferrari's commitment to the track has always extended well beyond the world of Formula 1 to include GT racing. GT competitions are part of Ferrari’s DNA. To be an innovative leader in the sport, Ferrari synergizes its efforts across different divisions; Competizioni GT leverages the best of breed in the race for continuous technological development.

Without simulation it would be virtually impossible to deliver results with the limited time frame available. Ferrari’s continuous investments in engineering simulation can be seen in the performance we achieve on the race track.

Our collaboration with Ansys started in 1998, when we were pioneering simulation tools to support the work of aerodynamicists. Simulation was a key advantage for us. As we grew our engineering team and its expertise, our expectations for Ansys also became more demanding. Our relationship with Ansys has kept growing, and in the last few years we have achieved unprecedented alignment in our vision for the evolution of a technical roadmap. Ansys has been a key technology partner in achieving our success.

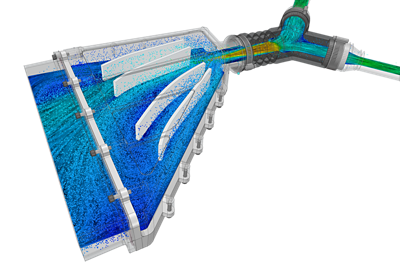

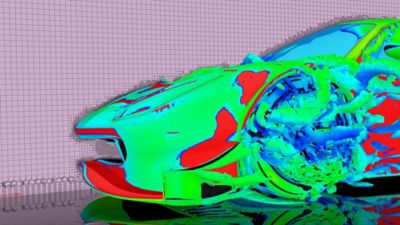

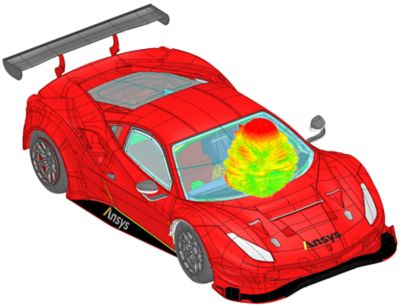

The Automated End To End Workflow For External Aero Performance Enables Ferrari To Run 3X As Many CFD Simulations In The Same Amount Of Time

- Ferrari engineers were able to increase their simulation productivity by 300% - placing new designs on the track in a fraction of the time required previously

- This automated workflow boosts productivity by reducing the user learning curve, minimizing the chance of human error and freeing engineers to focus on higher-value work.

- Now an entirely new vehicle geometry can be introduced and automatically meshed in just a few hours.

With Mosaic enabled meshes Ferrari engineers decreased the number of meshing cells by 15%

- Ferrari engineers have been able to decrease the number of meshing cells by 15%, while adopting mesh cell types that are yielding superior accuracy by the nature of their building blocks shape.

- This meshing capability also supports fully automated meshing, with little to no user intervention. Once a new design option has been defined, its surface mesh is automatically partitioned and sent to different cores of a distributed, parallel computing architecture.

- By batch executing the standard, repetitive tasks involved in meshing via Mosaic enabled technology - combined with robust Fluent Meshing native scripting - even less-experienced engineers can realize a 4-times speedup in meshing speed and efficiency.

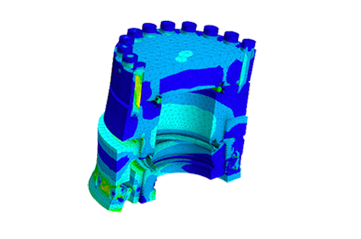

Ansys Fluent Accurate Solver Helps Ferrari To Deliver Solution Times That Are Twice As Fast

- The reduction on mesh size for a target accuracy, when combined with the new hex-dominant mesh, delivers solution times that are twice as fast.

- With Ansys Fluent the Ferrari GT engineering team can simulate and optimize the effects of air and other physical forces that will impact the vehicle's performance under real-world racing conditions.

In Real-Time: Ferrari Transitions from 4G to 5G Connectivity for the Win

Ferrari Competizioni GT is looking to 5G and Ansys simulation technology to boost connectivity and optimize data flow to leave their competition behind.