Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

앤시스는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

제품군

모든 제품 보기앤시스는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

앤시스는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

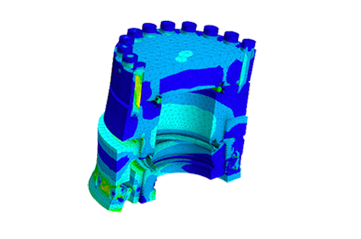

“Our goal in designing the new C130 jaw crusher was to deliver greater work capacity without increasing the weight of the machine. We used Ansys SpaceClaim to create multiple design alternatives and Ansys Mechanical to analyze these designs. The new design has a crushing capacity of 270 metric tons per hour and has the same weight as the previous model with a crushing capacity of 245 metric tons per hour. Ansys HPC played a key role by reducing the time to solve each design alternative from 21 hours to one hour.”

— Juuso Nänimäinen, Structural Analyst / Metso Outotec

Introduction

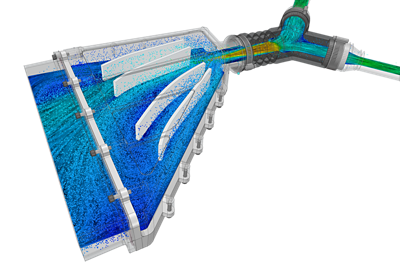

Metso jaw crushers reduce large rocks into smaller rocks or gravel by holding material between two solid surfaces and exerting enormous force — up to several meganewtons — to fracture the material. Metso engineers set out to substantially increase the work capacity of a new jaw crusher model while maintaining the same weight as the previous generation, which is crucial because jaw crushers are typically transported on public roads where load weights are limited.

Challenges

Metso used simulation in the design of previous products, but the geometrical complexity of jaw crushers limited the number of different alternatives that could be explored within time constraints. In the past, for example, it took 1,246 minutes (almost 21 hours) on a dual-core machine to solve a typical moving jaw non-linear model with 7 million degrees of freedom and 1.5 million elements.

Engineering Solution

美卓工程师使用Ansys SpaceCla万博im快速define the geometry of alternative designs using a direct modeling approach that creates the geometry as features or individual operations without requiring a network of constraints between the features. They solved each model in Ansys Mechanical on a high-performance computing (HPC) platform in only

78 minutes, 16 times faster than previous simulations. The HPC platform incorporated two Intel 10-core processors, 192 GB RAM and two NVIDIA Tesla graphics processing unit (GPU) acceleration cards. The ability to quickly generate and evaluate alternative designs made it possible for Metso engineers to rapidly improve the performance of the new design.

Benefits

Metso’s Ansys Mechanical PrepPost plus solver plus HPC license configuration makes it possible to do pre- and post-processing while the solver is running. By using Ansys HPC and with the assistance of Ansys channel partner EDRMedeso, Metso obtains more accurate results in substantially less time:

- Generated alternative designs seven to 20 times faster.

- Reduced analysis time from 4 hours to 15 minutes for small, yet non-linear models.

- Reduced analysis time from 4 days to 6.5 hours for large non-linear models with greater than 10 million degrees of freedom.

Ansys가 귀사를 위해 무엇을 할 수 있는지 알아보십시오.

Ansys가 귀사를 위해 무엇을 할 수 있는지 알아보십시오.

문의하기

문의해 주셔서 감사합니다!

We’re here to answer your questions and look forward to speaking with you. A member of our Ansys sales team will contact you shortly.